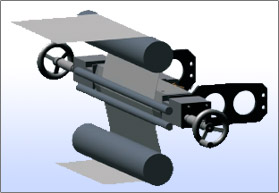

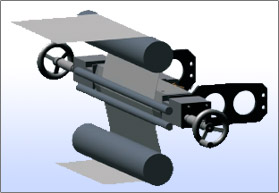

Profile Wrapping Application Systems

Rugged. Precise. Reliable.

|

Performance Applications

- Consistent, even adhesive coating at all machine speeds.

- Reduced adhesive usage.

- Eliminates waste and cleanup associated with glue roller.

- Reduces maintenance costs and downtime.

- Applies EVA or PUR hot-melts.

- Compact design allows for quick installation without product guide modifications.

- Side-to-side adjustment precisely lines up wrap.

- Back-up guide ensures uniform contact of wrap against head and kicks-out when machine stops.

|

|

|

|

- Automatic line speed-tracking ensures consistent glue volume at all speeds.

- Coating width and head position can be easily changed, even during production.

- Telescoping adjustment screws provide minimal overall head width.

- Hot-melt units available for any adhesive volume requirement.

- Unique grid melting systems reduce heat-up time.

Less Downtime - Better Production

P.E. hot-melt coating systems for profile wrapping are engineered to meet the demanding woodworking environment. Systems provide the customer with a superior quality product with considerable adhesive savings and minimum waste.

Touch Pad Control

Units feature an easy-to-use touch pad with a bright vacuum-flourescent screen which allows operators to quickly setup system parameters and monitor system operation.

Profile Wrapping Application System Specifications:

- Adjustable width applicator.

- High-flow inlet valve.

- Multiple mounting options available.

- Hardened paper engagement.

P.E. offers a complete selection of hot-melt components and support equipment:

- RTD hot-melt hoses

- Manual and automatic dispensing valves

- Nozzle and applicator styles

- Mounting bracket packages

- Solid-state pattern control systems

- In-line filters

- Replacement parts for competitive systems

- High-performance hot-melt adhesives

- Cost-effective rebuild/exchange programs

|