|

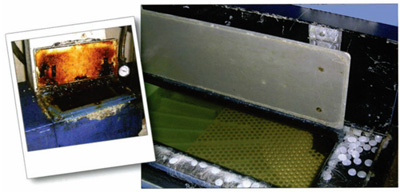

You'd be surprised at how many hot melt tanks we see that

look like the one on the left. It is the result of a standard

packaging hot melt being allowed to degrade - not only does it

look (and smell) awful, but it will lead directly to nozzle

blockages, production stoppages and increased costs.

Who wants that?

The tank on the right is filled with award winning* PE ultra

hot melt adhesive. After over a year's continuous production, it

remains clean, clear and odour free - and with no danger of

nozzle blockages, PE ultra helps to reduce total costs.

Consider all these extra benefits of using PE

- Versatile performance

Lower inventory costs

- Works all seasons.

- Fast and slow machines.

- Bonds a wide range of substrates.

- Proven to replace many other hot melts.

- High stability

Lower maintenance costs

- No charring, cleaner machines.

- Minimal downtime.

- Reduced parts costs.

- Cleaner running

Lower downtime costs

- Reduced stringing.

- No dripping from nozzles - or blocking.

- Reduced service time.

- Better to work with

Lower indirect costs

- Excellent thermal stability.

- No smell, no tainting.

- Approved for direct food contact,

PE-ultra 1 has been proven to be an excellent universal carton and case sealer. It performs well on the slowest

case packers and the fastest carton sealers (160 cartons per minute-typical) in both cold winter conditions and

hot summer conditions. In storage, the case/carton will retain bond integrity at high ambient temperatures and

low storage temperatures, down to -30c on untreated boards.

The "pearl white" of PE-ultra 1 highlights its quality, giving such benefits as low odour,

non-fuming and non-tainting, very important in food packing environments. It has the highest level of thermal

stability of any hot melt adhesive, which prevents nozzle blockages caused by the build up of char or gel.

PE-ultra 1 is clean running on jet, wheel and dauber systems and together with the excellent thermal stability cuts machine

downtime to an absolute minimum.

PE-ultra 1 has been formulated to give a medium to short open-time, high molten tack and a fast speed of set.

These characteristics, together with excellent adhesion to a wide range of boards, high heat resistance

(90c -25mm sq lap-shear/100g load) and low temperature resistance makes PE-ultra 1 the 1st choice in carton and case

sealing applications.

Methods of application

Jet, wheel or dauber. Suggested application temperature is 150c to 160c (depending upon substrates to be bonded). |